Material performance

Polypropylene (PP) is a high-quality material that has shown proven performance advantages since the 1950s. Since then, there has been an average global increase of 9% per year in the production and consumption of plastics, which has been driven by continuous innovations in the material. (PP was specified for the production of sewage pipes in the 1970s).

PP’s intrinsic properties of high-impact resistance combined with good stiffness and excellent chemical (see chemical resistance) and temperature resistance; good tensile strength; inertness toward acids, alkalis and solvents have secured its position for use in a wide range of consumer and industrial applications.

Polyolefin pipes show the lowest abrasion compared to other materials due to a very low surface roughness (approximately 0.007 mm). Due to this, PP pipes have excellent hydraulic capacity, allowing them to drain waste water even at low gradients.

See technical data and MSDS in the products section.

Acoustics

Noise pollution

The need to improve humankind’s quality of life has led to the treatment all types of pollution — most of which are created by humanity itself. Noise, particularly noise generated by people, is a treatable pollution in almost every living environment.

Disruptive noises in buildings have triggered the pursuit of solutions to minimize noise pollution. Architectural sound protection measures are most relevant in buildings where people spend relatively long periods (e.g., especially residences and offices). Disturbing noise is mainly caused by sources within the construction itself (“structure-borne noise”), most often from building engineering systems that either directly or indirectly give rise to noise.

Noise from wastewater and drainage systems

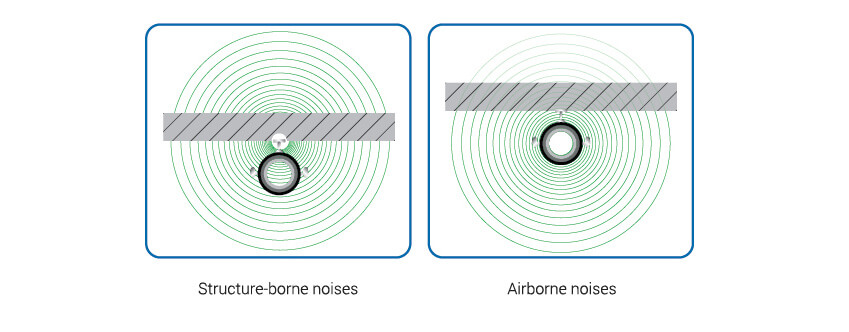

Every object in motion makes noise when it transmits vibrations – in the form of pressure or negative pressure waves – to the surrounding air. There are two types of noise in drainage and wastewater systems:

- Airborne noise – comes from pipelines and is generated by wastewater flowing inside. In this case, a soundproof drainage and wastewater system should limit the propagation of airborne noise and keep it inside the pipes. This is achieved by using a specially formulated material (using minerals), a triple layer pipe structure, high manufacturing processes and proper installation.

- Structure-borne – noise comes from pipes and fittings as well as the system used for affixing to the building’s structure such as brackets and clamps. This sound comes from the noise inside these systems, which makes them vibrate (acoustic resonance). The resonance is transmitted through the pipe clamps to the building’s structure and is heard in neighboring rooms as an irritating (acoustic wave) noise. In this case, it is important to connect the pipes and fittings to the building’s structure in such a way that the acoustic resonance is reduced to the minimum.

Read more on various aspects of acoustics

- Acoustic regulations for construction

- Noise sources and sound levels

- Consideration of noise insulation in the planning phase

- Fraunhofer® sound level measurement test

- Huliot Ultra Silent™ acoustic insulation performance

- nstallation with acoustic consideration of piping systems

- And more …

See the acoustics chapter.

Manuals

All Huliot’s products are lightweight, making them easy to handle. Both the push-fit ring seal method and the Thread-lock with O-ring method install quickly and easily, seal completely, and save time.

See or download the general manual for transportation, storage and installation, including repairs and irregular installations.

For each system and for most products, download instruction manuals from the downloads section and from each product system section.

See demos and examples of different application manuals in the media section and the product system section.

Repairing, adjustments and inserts

All Huliot systems are produced according to European diameter norms (DNs) and can connect to other systems produced from the same or other approved materials.

Huliot Ultra Silent, HT and Thread-lock™ systems diameters are approved according to EN1451, with external DNs 32, 40, 50, 63, 75, 90, 110, 125 and 160 mm. Huliot has a range of connectors that allow connecting with other systems such as PVC (DN 100), cast iron, asbestos and clay.

Inserting and repairing

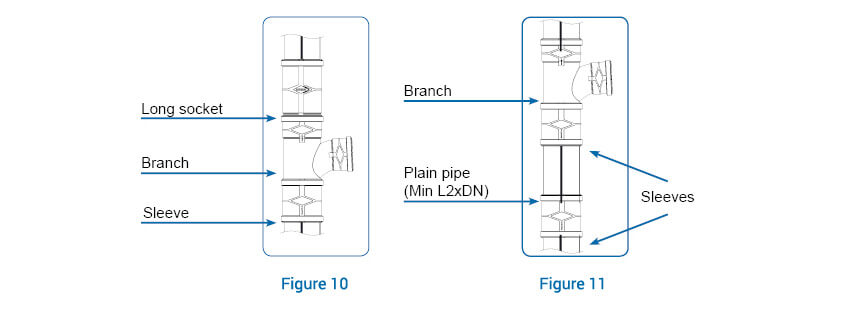

To add a branch (USEA) to an existing pipe with long socket (USTL) and sleeve (USU), follow these steps:

- Insert the plain end of the long socket into the branch socket and cut the equivalent of the socket length from the existing pipe piece.

- Insert the long socket into the upper pipe.

- Fix the sleeve on the lower pipe and slide the branch and long socket down into the sleeve (Figure 1). An alternate possibility is to use two sleeves and plain pipe. Note: The minimum plain pipe length must be more than double that of the external pipe diameter DN (Figure 2).

- To fix punctured or damaged pipe: Use the same methods with one socket pipe (USEM) instead of the branch and adding inspection pipe (USRE) or double branch (USDA).

See additional instructions for inserting and repairing in each product system section.

Standards and approvals

The principle of continuous improvement guides Huliot’s advanced production and inspection processes. The company’s state-of-the-art testing laboratories are central to our quality assurance program, ensuring that Huliot consistently adheres to standards of excellence. Huliot’s production facilities comply with international quality management standard ISO 9001

At Huliot, the concept of “quality” transcends production processes and product excellence to include the health, welfare and safety of our employees, protection of the environment, and exceptional customer service. In keeping with our policy of complete transparency, the company’s test results are always available to our customers.

The company is certified and compliant with ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018. Products are certified by SII, SKZ, DIBT, AENOR and DTI. Huliot’s products carry the Green Label, recognized by the World Green Building Council.

Download approvals and certifications from the downloads section and from each product system section.

Fire behavior

Huliot’s systems has been tested and certified according to the most stringent European standards for fire safety of building materials.

The Ultra Silent™ system is certified according to EN 13501-1:2009 by IBS and classified D-s2, d2. This standard defines classes of burning behavior for building materials and specifies the requirements and test methods for each class. The classification of reaction to fire and valid practical range of application is contained in the representational classification report. The Ultra Silent system is certified according to DIN 4102-1 by SKZ and classified B2. This standard defines classes of fire behavior for building materials and specifies the requirements and test methods for each class. The test method measures the ignitability of building products when exposed to a small flame.

Huliot offers the HT system B2 classification, according DIN 4102-1.

Guarantee

With more than 50 years’ experience, by using the latest technologies and the best raw materials and sealing fixtures from the world’s premium suppliers and by ensuring the production and logistics processes under the strictest quality control system, Huliot brings markets around the world the highest quality wastewater and drainage systems.

Huliot takes great pride in providing a 10-year warranty for its products and systems.

Architects and Planners Support

Detailed and millimeter accurate product drawings in several views offered clearly in REVIT format. In cultivation practices, the user integrates the products to scale in the design drawing. The products contained in 3D display.

Contact support

Huliot’s experienced engineers and experts in the fields of wastewater and drainage systems for construction and related topics provide technical support for planners, architects, plumbers and contractors.

Huliot’s team offers professional courses at the company’s training centers and at the customers’ premises around the world.

To contact our technical support team, please complete the contact application